3D PRINT

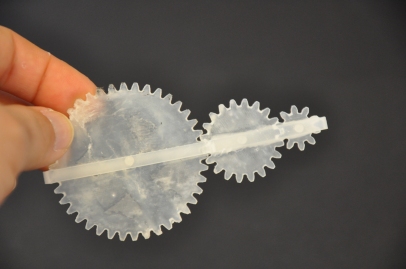

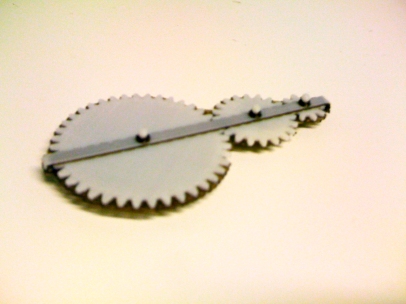

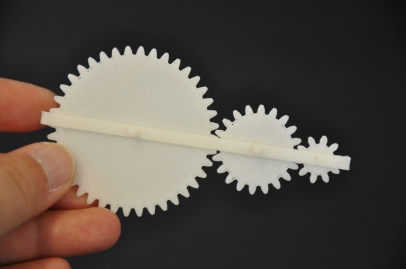

For the redo week, I decided to edit the Triple_GEAR project and 3D print on both the Dimension and InVision machine.

From InVision, remove model from aluminum tray by scraping the bottom layer of wax deposit. Place model in a domestic oven and set to convection bake at 150°. Let model bake for 1-1/2 to 2 hours.

Remove carefully after majority of the wax have melted. Some joints may be a bit soft at high temperature. Place model in oil bath to remove remaining wax.

From Dimension, slowly remove model from black plastic tray. Remove as much of the brown soluble support material carefully. This will reduce the amount of time it takes to dissolve the support material.

To access Stratasys WaterWorks, ask Tom or John to swipe you into E15-048. It takes 3 hrs to dissolve away every last bit of the brown support material.

WATER JET

Also, I decided to redo the water jet portion from the form work exercise. To begin, download the latest version of OMAX Layout. As it turns out, the problem I encountered regarding water jet cutting the previous week was due to using an older version of OMAX Layout. Import .DXF into OMAX Layout. Set line quality to 3. Set lead in/out by using autopath. Set tool path, and click on auto generate. Save file and open in OMAX Make. Set material to metal aluminum and thickness to 0.032″.

Move nozzle head to top left corner and set zero in both x and y direction. Click on “Begin Machining”.

The cut time is 11 minutes and 23 seconds.

Before starting, check to see that the water pipe and gas pipe are turned on. When both levers are aligned with pipe, it is turned on.

Next, lower the crank so that the nozzle touches aluminum sheet. Reverse the crank 1 full circle (1/2 circle kick back + 1/2 circle higher) to set appropriate nozzle height.

Finally, raise the water level and click start. Right click on pause after each path to remove cut piece. While this will make the process a few minutes longer, it will also reduce the chance of aluminum pieces 1. disappearing into the abyss or 2. floating around and interfering with the nozzle.