The goal of this project is to make an object / unit with operability using the 3D printing machines – InVision and Dimension.

Make Time:

- 2 hours – Design / Template .STL File

- unknown – 3D Print

- 3+ hour – WaterWorks @ 110°

Tools and Components:

- 3D System InVision SI2 3D Printer (Bedsize 11.75″ x 7.3″, 8″ high)

- Strataysys Dimension Elite 3D Printer ((Bedsize 8″ x 8″, 12″ high)

- .STL Template file

- Stratasys WaterWorks (for melting support plastic)

Directions:

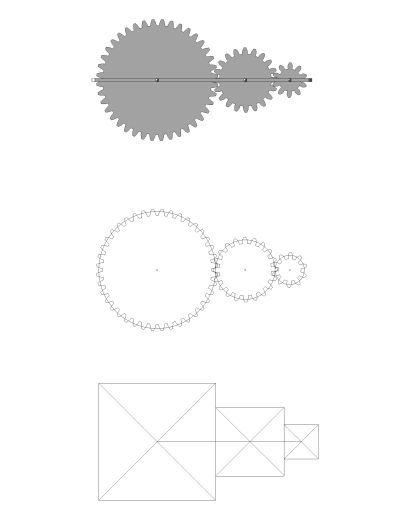

DESIGN. The gear unit is designed to be 2-3/4″ long x 1-1/2″ wide x 1/4″ thick, a triple gear combination that translates rotation from one to another. Using gear generation code from Rhino plug-in, select pitch circle and determine the number of teeth, module, pitch, press angle, bevel, and accuracy of gear. An offset of 0.001″ or larger is used in between all moving parts.

3D PRINT ON DIMENSION. The Stratasys Dimension Elite 3D printer uses ABSplus production-grade thermoplastic in ivory and a soluble support technology (SST) in brown as support material. Its precision is 0.007″.

Twist the black board to remove model.

Place 3D print model into Stratasys WaterWorks to melt the brown support material.

3D PRINT ON INVISION. The InVision SI2 3D printer uses VisiJet SR200 plastic, a natural translucent acrylic plastic, and VisiJet S100, a wax-like substance, as support material.

To remove model from aluminum plate, scrape at the base of the model and slowly lift it up.

The strap was too thin and broke while removing the 3D print model.