The goal of this project is to make a snap together construction kit using the abrasive water jet Omax 2652. I chose to make a desktop organizer in the spirit of the classic Vitra Uten.Silo designed by Dorothe Becker and Ingo Maurer.

Make Time:

- 2 hours – Design / Template File

- 1 hour – Water Jet

- 1/2 hour – Assembly

Tools and Components:

- Omax Water Jet 2652 (Bedsize 26″ x 52″)

- 1 sheet of 1/8″ aluminum sheet

- Template File

Directions:

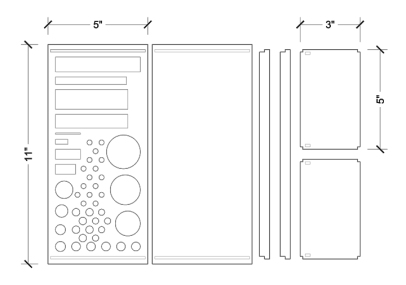

DESIGN. The desktop organizer is designed to be 3″ high x 5″ wide x 11″ long. Measure all items to be organized. Due to the lack of getting my hands on a caliper at the time of measurement, some of the holes were later determined to be a bit smaller. Slots were designed for aluminum pieces to press fit together.

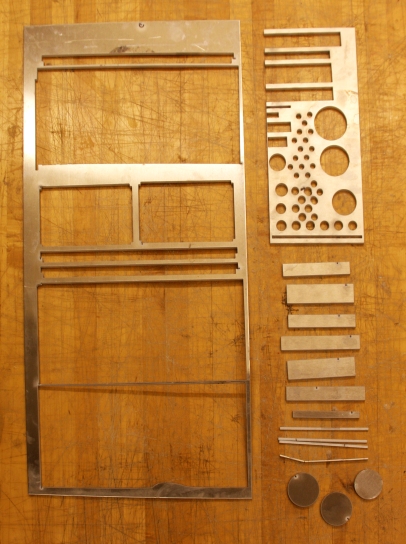

WATER JET. Prior to making cutting the aluminum. I made a chipboard mock up of the design. It turns out that I needed bracing pieces to prevent the organizer from collapsing.

After adding the appropriate bracing element, I also enlarged holes on the cut sheet for a better fit.

When making template file, make sure all vectors are joined. Save template file as .dxf. Open file in Omax Layout and set line quality to 3 (1 fast / more kerf – 5 slow / less kerf). Set lead in/out by using Autopath. Select tool path > auto generate. Save file and open in Omax Make. This will determine which side of the vector to offset. Start!

Total cut time for template file is 18 min.

There were two important lessons I learned during this process:

- Keep eyes on the machine at all times! Learn to position clamp on places that the machine will not knock into.

- If cut pieces are slender, chances are it will disappear into the bottom of the water jet. Possible changes is to orient the element perpendicular to the direction of the grills. Or, pause the water jet and grab the pieces before it finish cutting.

ASSEMBLY. Use a rubber mallet to assist press fit pieces to come together. No offsets were made on the notches. However, due to a very small kerf, all of the aluminum pieces fit very tightly together.

awesome!!!! thanks for posting your lessons learned too.