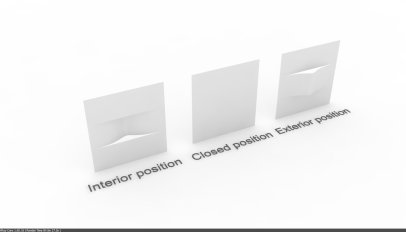

The aim of this project was the conceptualization, design and fabrication of an kinetic object utilizing gears. The idea behind this project was to build a gear system that can be used to move flexible panels to allow natural light to enter and natural circulation to take place. This project utilizes belt, rotational and horizontal gear systems.

- For this project you’ll need:

- One high torque electrical motor

- One power adaptor

- One 1/8″ sheet acrylic (18″ x 32″)

- Universal laser cutter

- One rubber band

Step one: Designing the systemIn a rough drawing set out the basic parameters and requirements for the system. Pay special attention to how the forces are to be transferred from one component to another. In this case belt, shaft and pressure surfaces were used.

Step two: Defining the gears

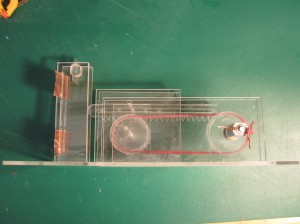

Since the aim of the design was not the increase or significant decrease of speed or torque from the motor gears and wheels of a standard size were decided on. The gear profiles were created by using the GearGen plugin for Rhino. The module used was 2.

Step 3: Fabricating the components

After the various components were designed in Rhino the design was converted to a two dimensional drawing, scaled for fabrication from a 1/8″ acrylic sheet. The pieces were cut on the Universal laser cutter and assembled using a general superglue.

The copper panels visible in the design were made from thin copper sheet cut and bent to shape.